Mini-lenses are revolutionizing the way we think about optics and light manipulation in today’s technology. Developed by Rob Devlin during his time at Harvard, these innovative devices, or metasurfaces, use an array of tiny pillars on a thin wafer to bend light, offering a more compact and cost-effective alternative to traditional lenses. With the startup Metalenz now producing millions of these mini-lenses for consumer electronics, their potential is being realized in high-demand products like the iPad and Samsung Galaxy S23 Ultra. As the technology continues to advance, mini-lenses not only contribute to improved camera systems but also open up exciting new avenues for polarization technology. As a result, the impact of these remarkable devices extends beyond personal gadgets, hinting at a future where metasurfaces redefine optics across various industries.

Also known as metasurfaces, mini-lenses represent a groundbreaking shift in optical device fabrication. These compact elements, characterized by their innovative design, harness the power of light in ways that traditional glass or plastic lenses cannot achieve. Led by pioneers like Rob Devlin and the startup Metalenz, this technology has paved the way for smaller, cheaper optical solutions particularly beneficial in the realm of consumer electronics. The ability of these devices to manipulate light at a nanoscale not only enhances existing applications but also inspires new uses in polarization technology and beyond. With major products now incorporating these devices, the landscape of optics is set for profound changes, merging advanced science with everyday technology.

Innovative Mini-Lenses Revolutionizing Consumer Electronics

The evolution of mini-lenses is transforming the landscape of consumer electronics. These small yet powerful devices, developed initially during Rob Devlin’s time at Harvard, are designed to manipulate light in ways that traditional lenses could not. Employing advanced metasurfaces, which utilize arrays of tiny pillars on an ultra-thin wafer, Metalenz has successfully created mini-lenses that are not only cost-effective but also allow for compact designs in smartphones and tablets. By revolutionizing the lens manufacturing process, these innovations help manufacturers maximize device functionality and aesthetics.

With demand for slimmer devices on the rise, the production of mini-lenses has surged, with Metalenz producing over 100 million of these metasurfaces. Companies like Apple and Samsung have reportedly integrated these innovative components into their flagship products, enhancing features such as depth-sensing capabilities and improving overall device performance. This groundbreaking technology represents a shift towards miniaturization in optics, paving the way for future advancements in how we interact with consumer electronics.

The Science Behind Metalenz and Metasurface Technology

Metasurfaces represent a significant breakthrough in optics, allowing for unprecedented control over light manipulation at the nanoscale. Rob Devlin’s contributions at Harvard’s Capasso Lab laid the foundational science for this technology, elevating the potential for metasurfaces in several applications. By fine-tuning nanostructures on these surfaces, researchers can dictate how light behaves, making it possible to focus it with efficiency previously thought unattainable. This capability is integral for advancing consumer electronics, where space and performance are critical.

The early research conducted by the team culminated in the development of the first functional metalens, which demonstrated the ability to concentrate light to a point, albeit with some limitations. In collaboration with semiconductor foundries, Metalenz has overcome many of these initial obstacles, leading to a production process that not only meets industry demands but also opens up new avenues for compact optical devices. This disruptive technology exemplifies the innovation fostered by university research, resulting in applications that extend beyond consumer electronics into areas like augmented reality and medical diagnostics.

Polarization Technology: A Game Changer for Security

Polarization technology heralds a new era in smartphone security, showcasing how Metalenz can leverage the properties of light for practical applications. Rob Devlin’s development of Polar ID illustrates how polarization cameras can dramatically reduce size and cost compared to traditional models. By integrating this technology into smartphones, users stand to gain enhanced security through improved facial recognition that accounts for unique polarization signatures. It’s an innovative approach that challenges the assumption that security measures must come at a premium.

The implications of this technology extend well beyond consumer devices; they also reach into healthcare and environmental monitoring, illustrating the versatility of polarization metasurfaces. For instance, in dermatology, the difference in polarization signatures between healthy and diseased skin could lead to earlier detection of skin cancers. Consequently, the adoption of polarization technology is poised to impact various sectors, all while driving down costs and making advanced detection methods accessible to a broader audience.

From Research Lab to Market Leaders in Technology

The transition from academic research to market-ready products can often be a daunting journey; however, Metalenz exemplifies a successful case where innovation flourished. The company, established in 2016, quickly transformed Rob Devlin’s groundbreaking concepts from the Capasso Lab into viable products that are now ubiquitous in daily consumer electronics. This progression underscores the powerful relationship between education and industry, which fosters an environment ripe for technological breakthroughs.

Metalenz’s ability to produce millions of mini-lenses demonstrates not just technical prowess but also an understanding of market needs. As competition accelerates, ensuring that these advanced optical components are widely adopted relies on ongoing innovation and improvement. Devlin’s vision for the future involves consistently pushing the boundaries of what is possible with metasurfaces, leveraging their collaborative roots to stay ahead in this rapidly evolving field of optics.

The Future of Mini-Lenses in Everyday Devices

As the tech industry continues to evolve, mini-lenses are expected to play an increasingly pivotal role in consumer electronics. The challenge lies in integrating these advanced optical technologies into existing and upcoming devices seamlessly. Companies invested in this technology, such as Metalenz, are at the forefront and are constantly seeking to enhance their products. The success of mini-lenses in high-demand devices indicates a tide shift where these components are set to become standard in future gadget designs.

Moreover, as the demand grows for compact devices that still perform at high levels, the mini-lens technology developed by Metalenz represents both a practical and forward-thinking solution. Innovations in size efficiency and cost-effectiveness will likely inspire an array of applications, such as in smart home devices, wearables, and even automotive technologies. The ongoing commitment to research and development by leaders in this field will ensure that the possibilities remain endless.

Rob Devlin: From Student to CEO

Rob Devlin’s journey from Harvard graduate student to CEO of Metalenz encapsulates the essence of entrepreneurial spirit fueled by innovation. His experience in the Capasso Lab, where significant research and experimentation took place, equipped him with the tools necessary to navigate the startup landscape successfully. Devlin’s leadership reflects a unique blend of scientific knowledge and business acumen, essential for driving the company toward greater horizons.

With a clear vision to advance metalenses and bring novel technologies to the consumer market, Devlin is not merely focused on immediate gains. Instead, he aims to cultivate long-term advancements that will continue to benefit users across various sectors. His journey serves as an inspiration not only for aspiring entrepreneurs but also for researchers looking to bridge the gap between lab innovations and real-world applications.

Metalenz’s Collaboration with Semiconductor Foundries

The partnership between Metalenz and major semiconductor foundries is instrumental in the large-scale production of mini-lenses, facilitating the rapid deployment of this groundbreaking technology. By leveraging existing manufacturing infrastructures that produce trillions of chips annually, Metalenz ensures that its metasurfaces can be integrated into the consumer market effectively. This strategy also alleviates potential bottlenecks that often accompany startup operations, allowing for swift scalability.

As the demand for advanced optics in consumer electronics grows, this collaboration is crucial for maintaining competitive advantages in cost and efficiency. The seamless production capabilities offered by semiconductor foundries directly contribute to the high-volume output of metasurfaces, substantiating the effectiveness of Metalenz’s innovative designs. The evolving relationship between this startup and established manufacturing giants exemplifies how cooperation can lead to substantial technological advancements.

Challenges and Competition in the Metasurface Market

Despite Metalenz’s early successes in the metasurface market, the landscape is dynamic and highly competitive. Other companies are investing heavily in research and development to catch up on the advancements pioneered by Devlin and his team. This competitive pressure necessitates constant innovation within Metalenz to maintain its leading position while exploring new applications for its technology.

To stay ahead, Metalenz must not only refine its existing products but also foresee the next wave of technological shifts that will impact consumer electronics. By continually improving upon their metasurfaces and strategically pivoting towards emerging trends, the company can ensure its relevance and dominance in the optics industry. The race is on, and with relentless innovation, the small team at Metalenz is equipped to face any challenges that arise.

Implications of Metasurfaces Beyond Consumer Electronics

While the integration of metasurfaces into consumer electronics is impressive, the potential applications extend far beyond this realm. Industries such as healthcare, automotive, and environmental science stand to gain significantly from these innovations. For example, the ability to harness polarization technology for safer diagnostic tools could revolutionize healthcare practices by providing instantaneous and accurate readings.

Moreover, the integration of metasurfaces into environmental monitoring devices could enhance the detection of pollutants and contribute to global sustainability efforts. As the technology matures, researchers are exploring ways to apply metasurfaces in various fields, demonstrating the breadth of possibilities these advancements afford. The technology born in an academic setting is poised to impact diverse sectors, leading to innovations that could reshape how society interacts with its environment.

Frequently Asked Questions

What are mini-lenses and how do they work in consumer electronics?

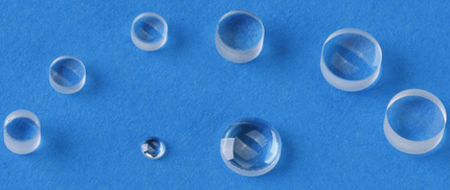

Mini-lenses, also known as metasurfaces, are innovative optical devices that use arrays of tiny pillars to manipulate light at a millimeter scale. Developed by Rob Devlin during his doctoral studies at Harvard, these mini-lenses are capable of focusing light much like traditional optics but in a more compact form, making them ideal for integration into consumer electronics like smartphones and tablets.

How did Metalenz innovate the lens manufacturing process with mini-lenses?

Metalenz revolutionized lens manufacturing by replacing traditional curved glass lenses with mini-lenses or metasurfaces. This approach drastically reduces size and weight, allowing manufacturers to incorporate more features in consumer devices without being constrained by bulky optics. Their product, developed from research in the Harvard Capasso Lab, exemplifies how technology can disrupt established industries.

What role do mini-lenses play in advanced features of smartphones, like facial recognition?

In advanced smartphone features like facial recognition, mini-lenses help enhance 3D sensing capabilities. Metalenz’s metasurfaces integrate with modules that emit near-infrared light, allowing for accurate depth mapping and reflection detection, which are essential for constructing 3D images and improving users’ security features.

How are mini-lenses produced in mass quantities for global markets?

Metalenz has scaled up production of mini-lenses through established semiconductor foundries, capable of manufacturing trillions of chips. By leveraging existing fabrication methods, the startup can produce high volumes of its metasurfaces, making them accessible in various consumer electronics while keeping costs low.

What is the potential of polarization technology in mini-lenses?

The potential of polarization technology in mini-lenses is significant, particularly with the upcoming Polar ID innovation from Metalenz. This technology utilizes light polarization to enhance smartphone security measures, being compact and cost-effective compared to traditional polarization cameras, which opens up additional applications across various fields, including healthcare and environmental monitoring.

What challenges do mini-lenses face in the competitive market of consumer electronics?

Mini-lenses, despite their innovative nature, face competition as various companies strive to replicate their technology. Metalenz’s advantage lies in its head start in both product implementation and continuous improvement of their metasurfaces, along with strategic collaborations with experts from the Capasso Lab, aiming to stay ahead in identifying new applications for their product.

How do mini-lenses differ from traditional lenses in terms of technology and application?

Mini-lenses, or metasurfaces, differ from traditional lenses primarily in their design and functionality. Unlike conventional optics that rely on curves and polished surfaces, mini-lenses leverage nanostructured surfaces to manipulate light. This allows for a thinner, lighter, and more versatile optical solution that can be applied in space-constrained environments like modern smartphones and tablets.

Can mini-lenses be used beyond consumer electronics?

Yes, mini-lenses have applications beyond consumer electronics. They can be used in fields such as medical imaging for detecting skin conditions through unique polarization signatures and in environmental monitoring to assess air quality. Their compact and adaptable nature positions them as a transformative technology in various sectors.

| Key Point | Details |

|---|---|

| Development of Mini-Lenses | Rob Devlin developed innovative mini-lenses during his Ph.D. at Harvard, experimenting with light-bending materials. |

| Mass Production | Metalenz has produced around 100 million metasurfaces that are used in consumer devices like the iPad and Google Pixel 8 Pro. |

| Industry Impact | Mini-lenses challenge traditional lens manufacturing, enabling slimmer designs for modern electronics. |

| Technology Development | Capasso’s lab started metasurfaces research in 2007; key papers laid the groundwork for successful prototypes. |

| Future Innovations | Metalenz is developing Polar ID technology to offer enhanced security features in smartphones and other devices. |

| Growing Opportunities | Metasurfaces have potential applications in various fields, including healthcare for skin cancer detection. |

Summary

Mini-lenses represent a revolutionary advancement in optical technology, blending cutting-edge research with practical applications. As demonstrated by Metalenz, these innovative devices, developed initially at Harvard, are transforming consumer electronics by reducing size and cost while enhancing functionality. With growing demands in the market, mini-lenses are set to play a critical role in the future of technology.